PCB dimensions: 350 × 300MM

Cycle time: 5.5 s

Screen frame dimensions: 736 × 736MM

Dimensions: 1220 × 2530 × 1444MM

Panasonic Screen printer SPD

Specifications:

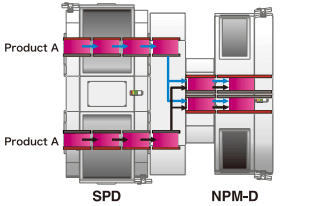

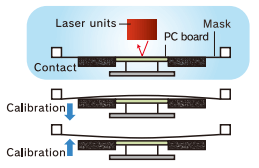

Dual printing stage that furthers productivity:

High-speed production

Printing the same product on the front and rear printing stages enables the creation of a high-production line.

Even for the single lane applied for the post process, the lane utilization can be enhanced by supplying PC boards from the front and rear stages.

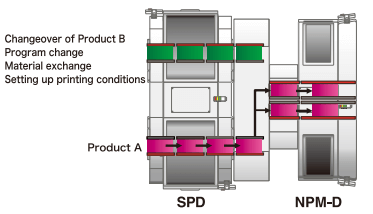

Nonstop changeover

The preparation for the next product can be carried out during one-sided stage production, thereby eliminating the time for changeover.

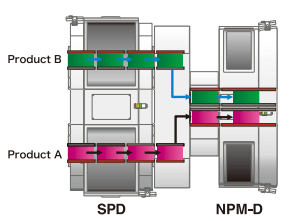

Production of different types of PC boards

Printing different products on the front and rear printing stages help enhance utilization and avoid the necessity for intermediate stock.

Higher quality & higher productivity. Further pursuing of high quality printing with "the cornerstone of quality is printing":

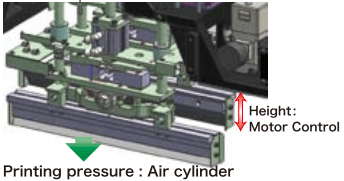

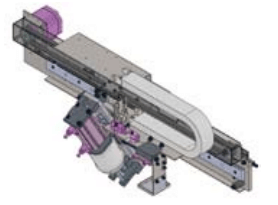

Hybrid squeegee head

Owing to the motor control of vertical squeegee motions in addition to the uni-floating printing method, we have achieved a reduction in printing time and the prevention of air entrapped in the solder paste.

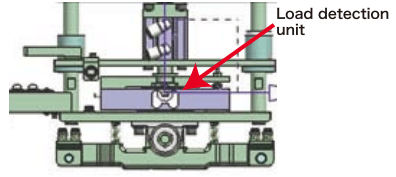

Load detection unit

The printing head is mounted with the load detection unit to monitor the printing pressure during printing.

Measuring the solder amount attached to the squeegee prevents solder amount shortages on the mask.

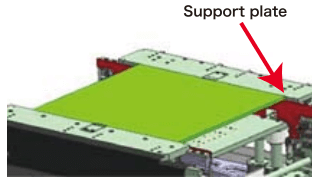

PCB support function

The support plates, integrated with the conveyor rails, support the back side of the PC board from end to end, which realizes the stabilization of printing quality.

A variety of options that increase quality and productivity:

Automatic solder supply unit (option)

Automatically supplying (X-direction movable)solder onto masks enables a long period of continuous printing.

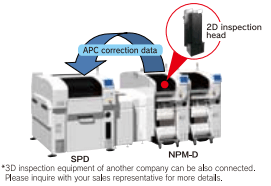

Inspection result feedback support (option)*

According to the correction data of shifted printing analyzed by solder paste inspection (APC correction data), it corrects printing positions (X,Y,θ)

Stencil height detection (option)

Laser processes can optimize a contact of PC boards with stencils so that stable printings can be provided

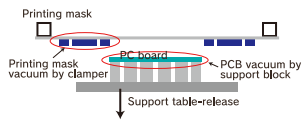

Mask vacuum support mask-release (option)

Printing mask can be vacuumed during printing and support-table release.

It can enable more stable rinting by eliminating shift and stick of a mask.

*3D inspection equipment of another company can be also connected. Please inquire with your sales representative for more details.

Model ID | |

Model No. | NM-EJP5A |

PCB dimensions (mm) | L 50 × W 50 to L 350 × W 300 |

Cycle time | 5.5 s (Including PCB recognition ) |

Repeatability | ±12.5 µm (Cpk□1.33) |

Screen frame dimensions (mm) | L 736 × W 736 (Optional support for other sizes) |

Electric source | 1-phase AC 200, 220, 230, 240 V ±10V 1.5 kVA |

Pneumatic source | 0.5 MPa, 60 L/min (A.N.R.) |

Dimensions (mm) | W 1 220 × D 2 530 × H 1 444 |

Weight | 2 250 kg |

*1: PCB exchange time varies depending on the machine in the pre-process and the post process, the PCB size, the use of a PCB pressing-down unit and so forth.

*2: For mask specifications, please see the specification.

*3: Including blower and vacuum pump"Option"

*4: Except for the signal tower and the touch panel.

*5: Excluding options, etc.

*Values such as cycle time and accuracy may vary depending on operating conditions.

*Please refer to the ‘‘Specification” booklet for details.

Keywords:

Panasonic SPG Stencil printer, Panasonic SPV Stencil printer, Panasonic SP70 Screen printer, DEK Stencil Printer, GKG Stencil printer, Panasonic pick and palce machine, Panasonic Inserter, Panasonic Printer, Panasonic Assembly Line, SMT Equipment, Panasonic Feeder, Panasonic Nozzle, Panasonic Spare parts, Panasonic AI Spare parts.

Contact: Tommy

Phone: +86 13691605420

E-mail: tommy@flason-smt.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China