Panasonic NPM-TT2 Pick and Place Machine

Max PCB:510 x 590mm

Application components:0402 (01005)

Compatible with lightweight 8-nozzle or 3-nozzle head V2

Panasonic NPM-TT2 Pick and Place Machine

Specifications:

Compatible with CM and NPM-series intelligent feeders & nozzles

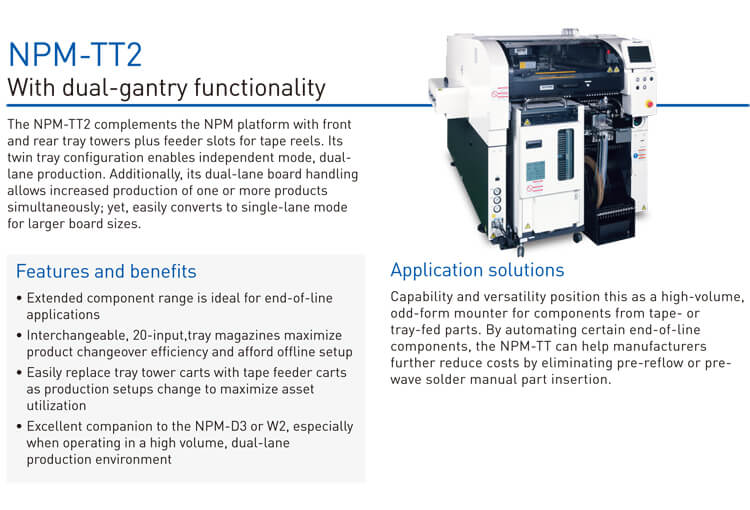

The NPM-TT2 (Next Production Modular-Twin Tray II) platform represents the next generation in twin tray modular production from Panasonic’s award-winning NPM platform—ideal for any mix.

Further bolstering the SMT process to accommodate more tray-supplied parts in full independently-run-lane mode, the NPM-TT2 processes boards up to 510 x 590mm and its dual lane functionality allows assembly of more of one product or two different products at the same time.

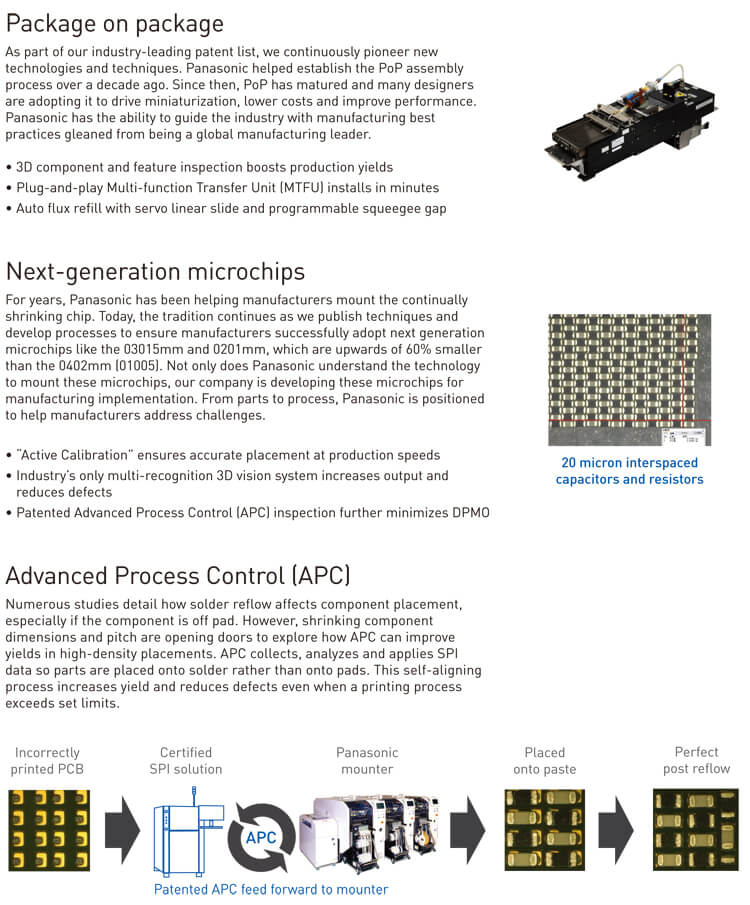

As common throughout the NPM-series, the NPM-TT2 features a Multi-Recognition Camera that increases processing speeds with a dynamic vertical-view of component condition and eliminating the need for a standard line cameras and independent 3D sensors.

With a new, advanced lightweight 3-nozzle head V2 (100N), pin-in-place lighting option and stackable stick feeders, the NPM-TT2 leads the way in terms of odd-placement capabilities.

Designed to blend seamlessly with other Panasonic NPM-series equipment as well at the NPM-DX, the NPM-TT2 optimizes throughput in a high-volume, dual-lane environment

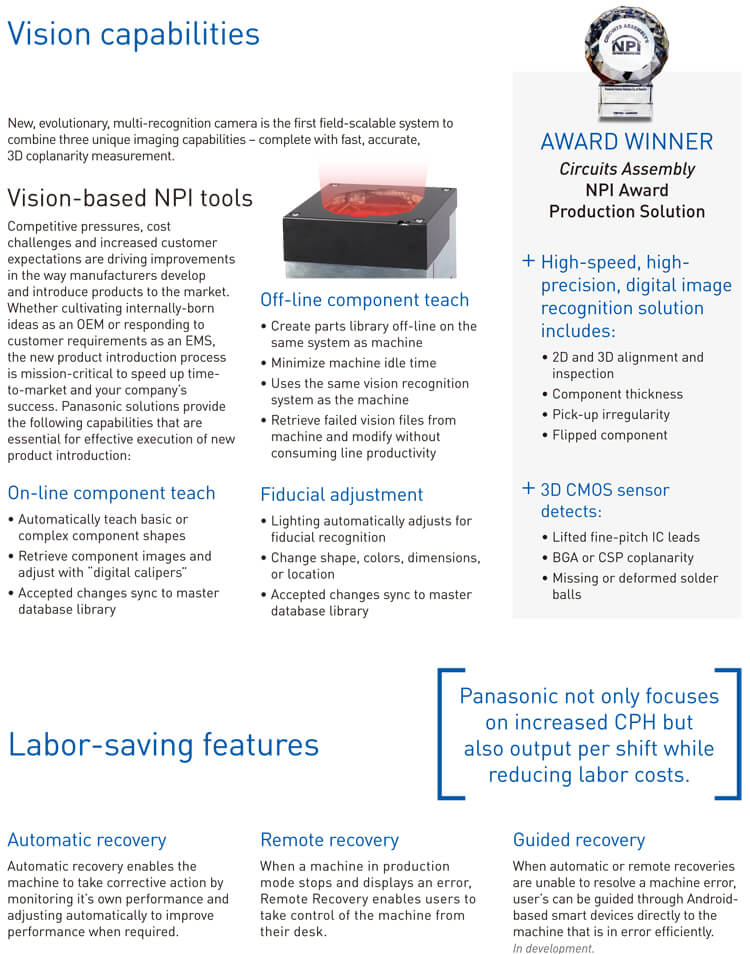

Model ID | ||||

PCB | PC size | Single-lane mode | L 50 x W 50 ~ L 510 x W 590 | |

Dual-lane mode | L 50 x W 50 ~ L 510 x W 300 | |||

M size | Single-lane mode | L 50 x W 50 ~ L 510 x W 510 | ||

Dual-lane mode | L 50 x W 50 ~ L 510 x W 260 | |||

PCB exchange time | Single-lane mode | 4.0 s (With no component mounted on the reverse side of PCB) | ||

Dual-lane mode | 0 s* *No 0s when cycle time is 4.0 s or less | |||

Electric source | 3-phase AC 200, 220, 380, 400, 420, 480 V 2.5 kVA | |||

Pneumatic source | Min.0.5 MPa, 200 L /min (A.N.R.) | |||

Dimensions *1 (mm) | W 1 300*2 x D 2 798*3 x H 1 444*4 | |||

Mass | 2 690 kg | |||

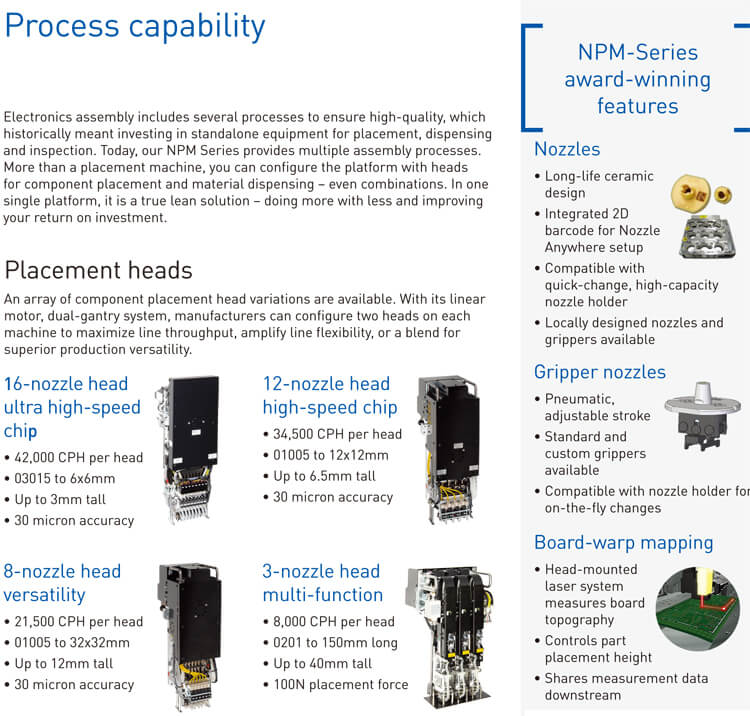

Placement head | Lightweight 8-nozzle head | 3-nozzle head V2 *5 | ||

Placement speed | PC size | 18 000 cph (0.20 s/chip) | 7 200 cph (0.50 s/chip) | |

M size | 17 460 cph (0.21s/chip) | 6 984 cph (0.52 s/chip) | ||

Placement accuracy | ± 40 µm/chip | ±40 μm/ chip | ||

Component | 0402 chip*6 to L 32 x W 32 x T 12 | 0603 chip to L 150 x W 25 (diagonal152) x T 30 | ||

Component | Taping | Tape : 4 to 56 / 72 mm | Tape : 4 to 56 / 72 / 88 / 104 mm | |

Specifications for front/rear tray feeders : Max.52 | ||||

Stick | Specifications for front/rear tray feeders : Max.12 (Single stick feeder) | |||

Specifications for front/rear feeder carts : Max.28 (Single stick feeder) | ||||

Tray | Max.40 (Front supply unit : Max. 20 + Rear supply unit : Max. 20) | |||

1 : Only for main body

2 : 1 820 mm in width if extension conveyors (260 mm) are placed on both sides

3 : Dimensions shown are specifications for front/rear tray feeders . Dimensions of specifications for front/rear feeder carts : 2 893 mm

4 : Excluding the monitor, signal tower and ceiling fan cover.

5 : 3-nozzle head V2 cannot be installed on NPM-D3

6 : The 0402 chip requires a specific nozzle/feeder.

Keywords:

Panasonic NPM-TT2 Pick and place machine, Panasonic NPM-D3 pick and place machine, Panasonic NPM-W2 pick and place machine, Panasonic NPM WX Pick and place machine, Panasonic pick and palce machine, Panasonic Inserter, Panasonic Printer, Panasonic Assembly Line, SMT Equipment, Panasonic Feeder, Panasonic Nozzle, Panasonic Spare parts, Panasonic AI Spare parts.

Contact: Tommy

Phone: +86 13691605420

E-mail: tommy@flason-smt.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China