Dimension: 5900*1520*1600mm

cooling zone: 3 zone

Heating zone: Top 10 and Botton 10

Max PCB width: 560MM

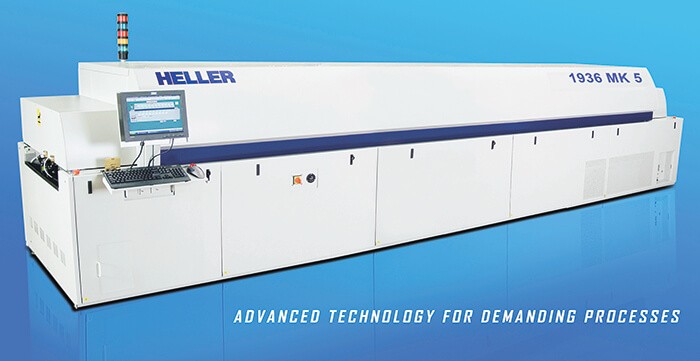

Heller Reflow Oven 1936 MK5

Specifications:

This reflow Oven machine’s new heating and cooling advances deliver up to a 40% reduction in nitrogen and electrical consumption! This makes our convection reflow oven machines not only the premier reflow soldering machine system but the best overall reflow oven value in the industry!

Advancements like the invention of the first waterless / filterless flux separation system earned Heller the prestigious Frost & Sullivan Award for Innovation in reflow oven soldering. But more importantly, this development extended preventative maintenance intervals from weeks to months for our systems. Additional breakthroughs in energy management have helped customers remain environmentally responsible while still maintaining their sustainability guidelines.

Model | ||

Model No. | 1936 MK5 (Air) | 1936 MK5 (Nitrogen) |

Electric Supply

Power Input (3 Phase) Standard | 480 volts | 480 volts |

Breaker Size | 100 amps @ 480v | 100 amps @ 480v |

kW | 9 - 15 Continuous | 9 - 15 Continuous |

Typical Run Current | 25 - 35 amps @ 480v | 25 - 35 amps @ 480v |

Optional Power Inputs Available | 208/240/380/400/415/440/480 VAC | 208/240/380/400/415/440/480 VAC |

Frequency | 50/60 Hz | 50/60 Hz |

Sequential Zone Turn On | S | S |

Dimensions

Overall Oven Dimensions | 232" (590cm) L x 60” (152cm) W x 63” (160cm) H | 232" (590cm) L x 60” (152cm) W x 63” (160cm) H |

Typical Net Weight | 5445 lbs. (2470 kg) | 6217 lbs. (2820 kg) |

Typical Shipping Weight | 6945 lbs. (3150 kg) | 7584 lbs. (3440 kg) |

Typical Shipping Dimension | 244” x 73” x 83” | 620 x 185 x 210 cm |

Computer Control

AMD or Intel Based Computer | S | S |

Flat Screen Monitor w/Mount | S | S |

Windows Operating System | Windows 10 Home | Windows 10 Home |

Auto Start Software | S | S |

Data Logging | S | S |

Password Protection | S | S |

LAN Networking | O | O |

Inert Atmosphere

Minimum PPM Oxygen | - | 10-25 PPM* |

Waterless Cooling w/ Flux Separation System | - | O |

Nitrogen On/OffValve | - | O |

Oxygen Monitoring System | - | O |

Nitrogen Standby System | - | O |

Typical Nitrogen Consumption | - | 500 - 700 SCFH ** |

Additional Features

KIC Profiling Software | S | S |

Signal Light Tower | S | S |

Powered Hood Lift | S | S |

Five (5)Thermocouple Profiling | S | S |

Redundant Alarm Sensors | O | O |

Intelligent Exhaust System | O | O |

KIC Profiler / ECD Profiler | O | O |

Center Board Support | O | O |

Board Drop Sensor | O | O |

Board Counter | O | O |

Bar Code Reader | O | O |

Custom Paint & Decal | O | O |

Battery Backup for Conveyor and PC | O | O |

GEM/SECS Interfacing | O | O |

Keywords:

SMT reflow oven machine, SMT wave soldering machine, SMT AOI machine, SMT SPI machine, SMT peripheral machine, Panasonic pick and palce machine, Panasonic Inserter, Panasonic Printer, Panasonic Assembly Line, SMT Equipment, Panasonic Feeder, Panasonic Nozzle, Panasonic Spare parts, Panasonic AI Spare parts.

Contact: Tommy

Phone: +86 13691605420

E-mail: tommy@flason-smt.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China