Heating Zone: Top 9, Bottom 9

Cooling Zone: Top 2

Overall Length: 4650MM

Max PCB width: 22 inch

Heller MK5 Reflow Oven-1809

Specifications:

New Low Height Top Shell

New low height top shell provides much easier access for operators. All skins have double insulation to save up to 10-15% in en ergy costs.

MK7 Enhanced Low Height Heater Modules

Enhanced low height heater module provides the lowest Delta Ts on the product with better air flow and uniformity! The Uniform Gas Management system eliminates “net flow” which results in nitrogen consumption reductions of up to 40%! New semi-circular heater is more robust and efficient with much longer life time.

Revolutionary Flux Management System

Our revolutionary flux collection system traps the flux in collection jars that can be easily removed and replaced while the oven is running — saving time consuming P.M. The new flux filtration box also has no risk of flux clogging for a longer term P.M. interval. Additionally, our proprietary Flux-Free Grill system limits the flux residue on the cooling grills giving the Heller system the highest production yields of any oven!

Internet of Manufacturing (IoM) —Smart factories, intelligent machines and networked processes through the use of cyber-physical systems.

Heller offers Host Computer/IoM Interfacing.

This integration provides:

• Central control

• Production reporting — # of boards processed, up time, down time

• MTBF / MTTA / MTTR

• Energy management and control

• Traceability of product

Heller offers compatible interfacing for:

-CFX (AMQP MQTT)

-Hermes

-PanaCIM

-Fuji Smart Factory

-ASM

-Custom interfaces available upon request

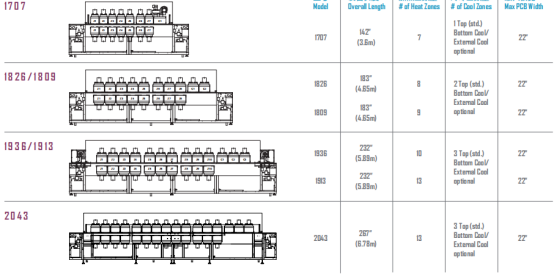

NOTE: 1826+1936+2043 models utilize a 30” wide by 12” long heater module to allow drop-in profile compatibility with other vendors’ ovens. 1707+1809+1913 models utilize a 30” wide by 10” long

heater module to provide improved profile “sculpting” and reduced liquid times. Module sizes up to 36” wide are available upon request for large boards up to 28” wide and increased dual rail width.

Keywords:

SMT reflow oven machine, SMT wave soldering machine, SMT AOI machine, SMT SPI machine, SMT peripheral machine, Panasonic pick and palce machine, Panasonic Inserter, Panasonic Printer, Panasonic Assembly Line, SMT Equipment, Panasonic Feeder, Panasonic Nozzle, Panasonic Spare parts, Panasonic AI Spare parts.

Contact: Tommy

Phone: +86 13691605420

E-mail: tommy@flason-smt.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China